product name:

4 6 8 awg rubber welding cable

product properties

Brand: Yiteng

Model: YC YH YCW

Certification: CE ISO CCC

Origin: hebei

Trading Information

Minimum order quantity: 1000meters

Price: USD 1-30 per meter

Payment method: T/T L/C DA DP Western Union

Supply Ability: 10000meters per week

Delivery date: 10-15days after payment

Conventional packaging: 100meters per package or in wooden drum

product description

>>>>>>>>![]() sales@cablesyt.com>>>>>>>>

sales@cablesyt.com>>>>>>>>

Detailed Product Description:

Service Conditions

This product is suitable for the welding machine whose voltage to the ground is not more than 200V and

pu lsating current value is 400V.

Model, Names Main applications and Work In the Temperature

| Product Name | Welding cable |

| Product standard | AS/NZS3191 Generally to AS/NZS 5000.1 |

| Core | Single(Optional) |

| Working Life | < 25 years |

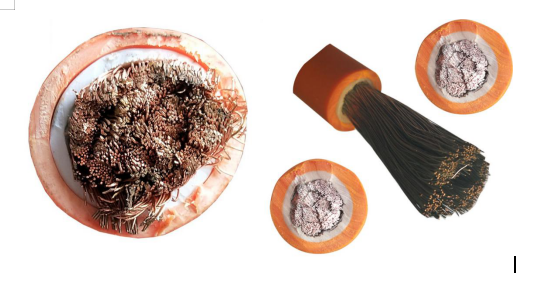

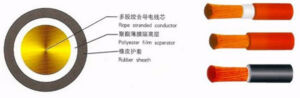

| Type of conductor | pure copper,tinned copper |

| Material of conductor | Copper/aluminum |

| Material of insulation | Pvc/rubber |

| Color of core insulation | Red/white/blue/black/green/yellow(optional) |

| Material of Jacket | Pvc/rubber/as your requirment |

| Voltage | 250/440v,300v/500v,450/750v |

| Advantage | Flame resistant/low smoke/halogen free |

| Section | 10mm2-400mm2 |

| Property | Heat-resistant |

Technical data & size Rubber Welding Cable. single layer sheated

| Nominal Section-Area of Conductor(mm2) | Structure of Conductor | Nominal Thik-ness of Sheath (mm) | Overall Diameter | Max. Conductor Resistance at 20º C (Ω /km) | Approx. Weight (kg/km) | ||

| Core no. /Dia. (no. /mm) | Min. | Max. | YH | YHF | |||

| 10 | 322/0.20 | 1.8 | 7.5 | 9.7 | 1.91 | 146 | 153.51 |

| 16 | 513/0.20 | 2.0 | 9.2 | 11.5 | 1.16 | 218.9 | 230.44 |

| 25 | 798/0.20 | 2.0 | 10.5 | 13.0 | 0.758 | 316.6 | 331.15 |

| 35 | 1121/0.20 | 2.0 | 11.5 | 14.5 | 0.536 | 426 | 439.87 |

| 50 | 1596/0.20 | 2.2 | 13.5 | 17.0 | 0.379 | 592.47 | 610.55 |

| 70 | 2214/0.20 | 2.4 | 15.0 | 19.5 | 0.268 | 790 | 817.52 |

| 95 | 2997/0.20 | 2.6 | 17.0 | 22.0 | 0.198 | 1066.17 | 1102.97 |

| 120 | 1702/0.30 | 2.8 | 19.0 | 24.0 | 0.161 | 1348.25 | 1392.55 |

| 150 | 2135/0.30 | 3.0 | 21.0 | 27.0 | 0.128 | 1648.5 | 1698.72 |

| 185 | 1443/0.40 | 3.2 | 22.0 | 29.0 | 0.106 | 1983.8 | 2020.74 |

Electrical data sheet

| electrical characters | Current rating for single duty cycle operation over a period of 5 minutes | |||||

| cross section | 100% | 80% | 60% | 35% | DC resistance Ohm @20℃/km | |

| 10 mm² | 100A | 103A | 108A | 122A | 1.91 | |

| 16 mm² | 135A | 145A | 175A | 230A | 1.21 | |

| 25 mm² | 180A | 195A | 230A | 300A | 0.78 | |

| 35 mm² | 220A | 240A | 290A | 375A | 0.554 | |

| 70 mm² | 350A | 380A | 460A | 600A | 0.272 | |

| 95 mm² | 420A | 470A | 560A | 730A | 0.206 | |

| 120 mm² | 500A | 540A | 650A | 850A | 0.161 | |

| 150 mm² | 580A | 630A | 750A | 980A | 0.129 | |

| Note: Ambient air temperature 25℃/ Maximum conductor temperature 85℃. As conductor temperature varies according to the time in use as well as current, ratings shown are given as a guide | ||||||

| Advantages: | oil and water proof/ wearing proof/ acid and alklai resistance/weahter proof | |||||

>>>>>>>>![]() sales@cablesyt.com>>>>>>>>

sales@cablesyt.com>>>>>>>>

Type and Name of welding cable:

| Type | International type | Name | Long-term working temperature of wire core |

| 60245IEC81 (YH) | H01N2-D (Common flexible) |

Rubber sheathed welding cable | lower than 65℃ |

| 60245IEC82 (YHF) | H01N2-E (Extra flexible) |

Neoprene or other equivalent synthetic elastomer rubber sheathed welding cable |

>>>>>>>>![]() sales@cablesyt.com>>>>>>>>

sales@cablesyt.com>>>>>>>>

5. electrical performances

electrical characteristics

| H01N2-D Datasheet | ||||||

| Item | conductor structure | Stranded OD MM | Insulation thickness MM | Sheath thicknessMM | Appr OD MM | Appr Weight KG/KM |

| 1C10 | 318/0.2mm | 4.3 | 1.3 | 1.3 | 9.5±1 | 185 |

| 1C16 | 509/0.2mm | 5.3 | 1.4 | 1.4 | 10.9±1 | 257 |

| 1C25 | 796/0.2mm | 6.2 | 1.6 | 1.6 | 12.6±1 | 360 |

| 1C35 | 1115/0.20mm | 7.8 | 1.7 | 1.8 | 14.5±1 | 490 |

| 1C50 | 1592/0.20mm | 9.4 | 1.7 | 1.8 | 16±1 | 680 |

| 1C70 | 2210/0.20mm | 11.4 | 1.8 | 2.2 | 20±1 | 920 |

| 1C95 | 3025/0.20mm | 12.9 | 2 | 2.5 | 23±1 | 1264 |

| 1C120 | 3820/0.20mm | 15.2 | 2.2 | 2.5 | 24.6±1 | 1693 |

| 1C150 | 3050/0.25mm | 17 | 2.2 | 2.5 | 26.4±1 | 2103 |

| 1C185 | 3770/0.25mm | 18.6 | 2.5 | 2.5 | 28.6±1 | 2610 |

| printing: | YR NOV 2020 1C35MM² CU/ EPDM/ CPE -40℃ ~105℃ 0001M or as per requirement | |||||

| copper: | 99.99% purity annealled copper class5 | |||||

| insulation: | EPDM rubber | working temp -40℃ to 105℃ | white color | |||

| sheath: | CPE / Neoprene rubber | working temp -40℃ to 105℃ | black color | |||

| standard: | Confirmity to CE / ISO9001 / BS / Rohs / IEC | |||||

| rated voltage | 100V | |||||

| Min bending radius | 6 times Overall diamter | |||||

| electrical characters | Current rating for single duty cycle operation over a period of 5 minutes | |||||

| cross section | 100% | 80% | 60% | 35% | DC resistance Ohm @20℃/km | |

| 10 mm² | 100A | 103A | 108A | 122A | 1.91 | |

| 16 mm² | 135A | 145A | 175A | 230A | 1.21 | |

| 25 mm² | 180A | 195A | 230A | 300A | 0.78 | |

| 35 mm² | 220A | 240A | 290A | 375A | 0.554 | |

| 70 mm² | 350A | 380A | 460A | 600A | 0.272 | |

| 95 mm² | 420A | 470A | 560A | 730A | 0.206 | |

| 120 mm² | 500A | 540A | 650A | 850A | 0.161 | |

| 150 mm² | 580A | 630A | 750A | 980A | 0.129 | |

| Note: Ambient air temperature 25℃/ Maximum conductor temperature 85℃. As conductor temperature varies according to the time in use as well as current, ratings shown are given as a guide | ||||||

| Advantages: | oil and water proof/ wearing proof/ acid and alklai resistance/weahter proof | |||||

Application: Welding cables are used for connecting the electrodes to the welding equipment,charger machine.

These cables are suitable for welding equipment,charger machine in industry , in automated welding equipment,

in tooling constructions, automobile and ship building as well as for handheld electrodes in workshops and at

building sites.These flexible and robust currentcarrying cables are suitable for use at high mechanicalloads in

dry indoors.

>>>>>>>>![]() sales@cablesyt.com>>>>>>>>

sales@cablesyt.com>>>>>>>>

Packaging & Shipping

Packaged with Standard Export Wooden or Steel Drums or as per Customer’s Requirement

Shipped within 7-15 Days once Order Confirmed