CCA (Copper Clad Aluminum) wire is a commonly used wire material, which consists of an aluminum core and a copper coating. Here is an overview of CCA conductors:

Introduction to CCA conductors

1. Material composition

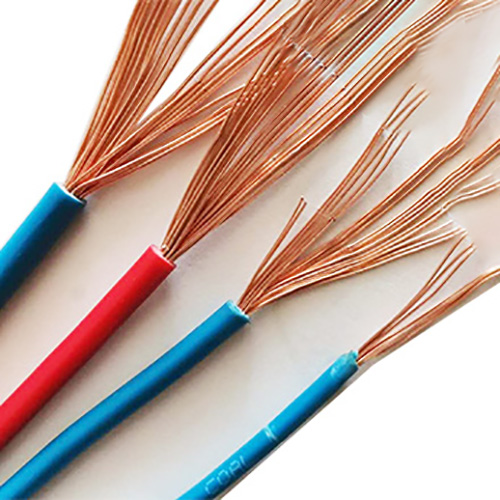

Aluminum core: The center of the conductor is made of pure aluminum, which is light and low in cost, but its conductivity is not as good as copper.

Copper cladding: Surrounding the aluminum core is a thin layer of copper, which has good conductivity but is more expensive. This copper cladding can improve the conductivity of the conductor while reducing costs.

2. Characteristics

Light weight: Compared with all-copper conductors, CCA conductors are lighter overall due to the small specific gravity of aluminum.

Cost-effectiveness: The copper cladding allows CCA conductors to provide performance close to that of pure copper conductors while being less expensive.

Corrosion resistance: The copper cladding outside the aluminum core can provide some corrosion protection.

Strength and flexibility: CCA conductors combine the flexibility of aluminum with the strength of copper.

3. Application areas

Communication industry: used for networks, telephone lines, etc.

Cable manufacturing: used to manufacture various power lines and signal lines.

Building wiring: used for wiring in houses and commercial buildings.

4. Precautions

Temperature Management: In high temperature environments, aluminum has a different expansion coefficient than copper, which may affect the stability and performance of the wire.

Connection Points: At the connection points, special attention may be required to ensure good electrical contact between the aluminum core and the copper cladding to prevent corrosion problems.

Please note that the above is an overview based on general knowledge, and the actual use of CCA wires should follow specific product specifications and industry standards. If you need to create more detailed documents, reports or other related materials, please provide further instructions or requirements.